Diesel Pump Stop Solenoid Valve: Role, Functioning, Choice, and Installation

The diesel pump stop solenoid valve is a key component of the injection system in diesel engines. It controls the fuel supply and allows the engine to stop or start by acting on the injection pump.

What is a Solenoid Valve?

The diesel pump stop solenoid valve is an essential component in diesel engine management systems. Its main role is to interrupt the fuel supply when the engine is turned off.

It operates electrically, opening or closing in response to an electrical command, usually issued by the engine's ECU (Electronic Control Unit). When it receives a stop signal, the solenoid valve instantly cuts off the fuel flow to the injection pump, leading to engine shutdown. In addition to this controlled stop, it helps prevent unintentional starts and secures the engine.

Main Functions of the Stop Solenoid Valve

- Engine Shutdown: When activated, it cuts off the fuel supply, thus stopping the engine in a controlled manner.

- Fuel Control: It allows for the starting or stopping of fuel injection based on demand.

- Safety: It plays a role in safety systems by cutting fuel in case of emergency or anomaly.

How to Choose a Solenoid Valve?

To choose the right diesel pump stop solenoid valve, it is essential to consider several criteria:

- Compatibility: Ensure the solenoid valve is compatible with the type of diesel engine and injection pump you are using. Check original references or consult manufacturer specifications to avoid any adaptation errors.

- Technical Specifications: Solenoid valves operate at different voltages (12V, 24V, etc.). It is crucial to select a solenoid valve compatible with your vehicle or equipment's electrical circuit.

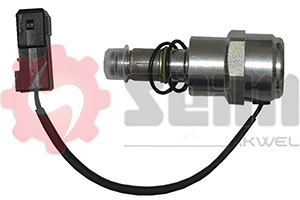

- Connectors: Ensure the connector matches that of your vehicle.

Installation of the Solenoid Valve

The installation of the solenoid valve can be performed by a professional or by yourself if you have the necessary skills. Here’s a simplified guide to help you:

- Preparation: Before proceeding with installation or replacement, disconnect your vehicle’s battery to avoid any risk of short circuit.

- Removal of the Old Solenoid Valve: Locate the defective solenoid valve, disconnect the connectors, and remove it following the manufacturer's instructions.

- Installation of the New Solenoid Valve: Position the new solenoid valve in place, secure it properly, and reconnect the connectors.

- Testing: Restart the vehicle and check the proper functioning of the newly installed solenoid valve. Note that some solenoid valves may require coding.

Coding of the Solenoid Valve

Coding is an important step to ensure that the solenoid valve functions correctly with the engine's electronic system. Here are some tips to follow:

- Accessing the ECU (Electronic Control Unit): The stop solenoid valve must be correctly coded to work with the engine's ECU. This may require using a diagnostic tool or specific software provided by the vehicle manufacturer.

- Updating Parameters: During coding, it is important to update the ECU parameters to include the new solenoid valve. This will allow the ECU to recognize the new component and communicate correctly with it.

- Testing and Calibration: After coding, it is recommended to test the system to ensure the solenoid valve's command is synchronized with other engine components. If necessary, make adjustments and recalibrations to optimize its functioning.

- Error Monitoring: Use a diagnostic tool to check that no error codes appear after installation. If errors arise, it may indicate a coding or compatibility issue with the ECU.

- Testing the Solenoid Valve: Restart the vehicle and verify the proper functioning of the newly installed solenoid valve.

With careful installation and proper coding, your stop solenoid valve will ensure safe and efficient management of your diesel pump, providing optimal longevity and performance for your engine.

Maintenance of Solenoid Valves

To ensure the longevity and accuracy of your solenoid valves, regular maintenance is necessary. Here are some tips:

- Cleaning: Keep the solenoid valve clean to prevent dirt accumulation that could affect its performance.

- Regular Inspection: Regularly check the condition of the solenoid valve for any signs of wear or malfunction.

- Preventive Replacement: Replace the solenoid valve at regular intervals according to the manufacturer's recommendations to avoid unexpected failures.

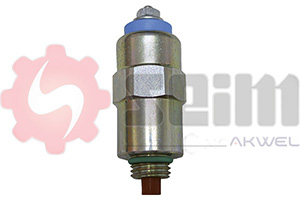

Discover the SEIM solenoid valves now!

The diesel pump stop solenoid valve is an essential component for controlling fuel supply and ensuring safe engine shutdown. Contact us today to learn more and discover how our solenoid valves can guarantee the proper functioning of your vehicle.

SEIM - Your Partner for Reliable and High-Performance Solutions