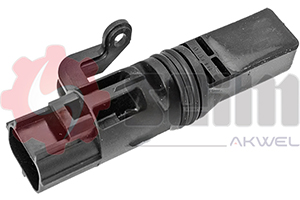

Crankshaft Position Sensor SEIM: Functioning, Role, Selection, and Installation

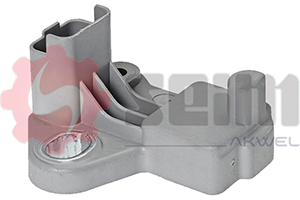

The crankshaft position sensor is an essential component in the engine management system. It monitors the rotation of the crankshaft and transmits this information to the Engine Control Unit (ECU) to synchronize ignition and fuel injection.

What is a Crankshaft Position Sensor?

The crankshaft position sensor, also known as a CKP, continuously monitors the position and rotational speed of the crankshaft, the component that converts the linear movements of the pistons into rotation. This sensor is essential for enabling the ECU to calculate the optimal timing for ignition and fuel injection into the cylinders.

Main Functions of the Crankshaft Position Sensor:

- Synchronization of Ignition and Injection: The sensor sends real-time information to the ECU to ensure that ignition and fuel injection occur at the precise moment.

- Optimization of Engine Performance: By allowing perfect synchronization, it helps improve power, fuel consumption, and reduce harmful emissions.

- Prevention of Engine Malfunctions: A faulty sensor can lead to misfires, engine stalls, or even prevent the vehicle from starting.

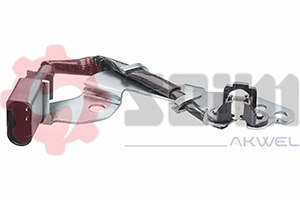

The sensor typically operates via the Hall effect or variable reluctance, detecting the passage of teeth or targets on the crankshaft, which generates an electrical signal transmitted to the ECU.

How to Choose a Crankshaft Position Sensor?

Choosing the right crankshaft position sensor is crucial for ensuring the proper functioning of your engine. Here are the criteria to consider when making your selection:

- Compatibility with the Vehicle: Each vehicle requires a specific sensor. It is essential to choose a sensor that is compatible with your vehicle and engine model. Check the original references or consult the manufacturer's specifications to avoid fitting errors.

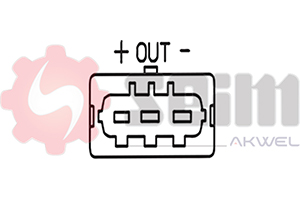

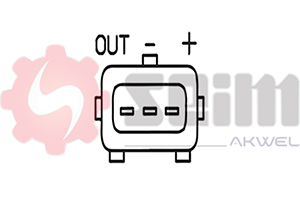

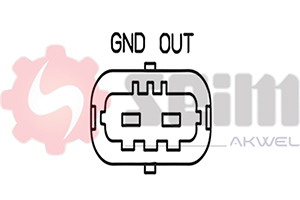

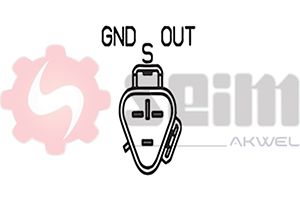

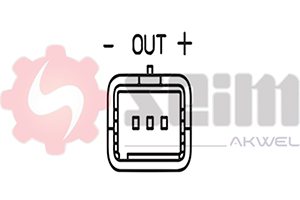

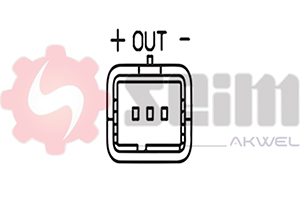

- Type of Sensor (Hall effect or variable reluctance):

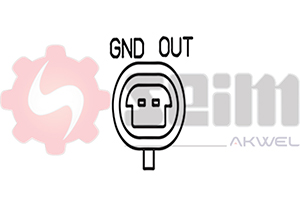

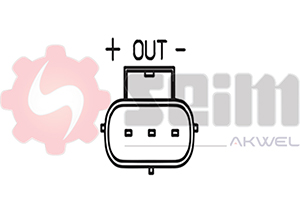

- Hall Effect: These sensors operate from a magnetic field and generate a digital signal. They are often more accurate and resistant to interference.

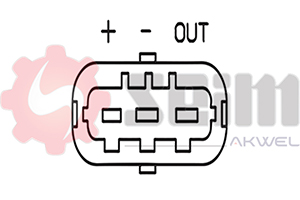

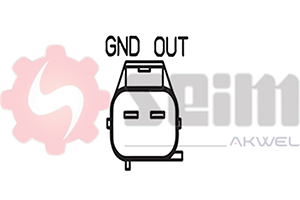

- Variable Reluctance: These sensors measure the variation in the magnetic field between the teeth of a target wheel and produce an analog signal.

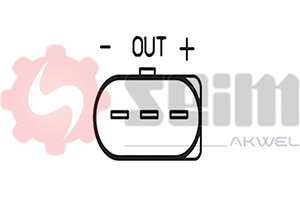

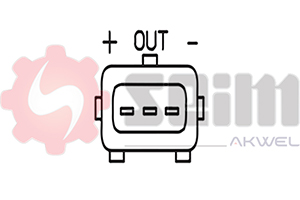

- Connectors: Ensure that the connector matches that of your vehicle.

A quality sensor must provide accurate and timely information to the ECU to avoid delays in engine management.

Installation of Crankshaft Position Sensors

The installation of crankshaft position sensors can be performed by a professional or by yourself if you have the necessary skills. Here’s a simplified guide to help you:

- Preparation: Before installation or replacement, disconnect your vehicle’s battery to avoid any risk of short circuit or damage to the ECU.

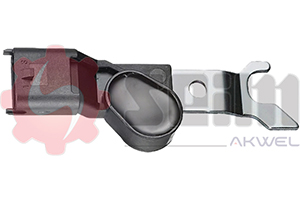

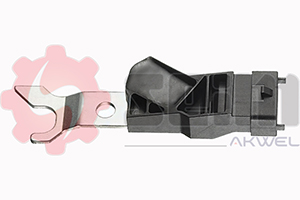

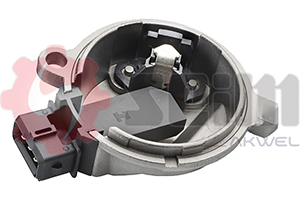

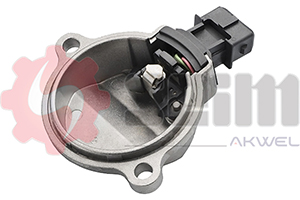

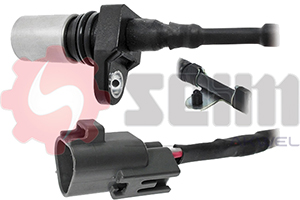

- Locating the Crankshaft Sensor: The sensor is generally mounted near the crankshaft, often at the level of the clutch bell or the crankshaft pulley. Consult your vehicle’s manual for the exact location.

- Removing the Old Sensor: Disconnect the electrical connectors from the faulty sensor, then remove the screws holding it in place. Be careful not to damage the wires.

- Installing the New Sensor: Place the new sensor in the location of the old one, ensuring it is properly aligned with the target wheel or flywheel teeth.

- Testing Functionality: After installation, reconnect the battery and start the engine to test its functionality. If the engine runs unevenly or if a check engine light appears, it may indicate a problem with the new sensor or improper installation.

- Electronic Diagnosis (if necessary): If errors appear, use an OBD diagnostic tool to reset the ECU or identify anomalies. Some systems may require an ECU reset after installing a new sensor.

Maintenance of Crankshaft Position Sensors

To ensure the longevity and accuracy of your crankshaft sensors, regular maintenance is necessary. Here are some tips:

- Cleaning: Keep the sensors clean to avoid dirt buildup that could affect their performance.

- Regular Inspection: Regularly check the condition of the sensors for any signs of wear or malfunction.

- Preventive Replacement: Replace the sensors at regular intervals according to the manufacturer's recommendations to avoid unexpected failures.

Discover SEIM Crankshaft Position Sensors Now!

The crankshaft position sensor is essential for precise management of ignition and injection in the engine. A faulty sensor can lead to major malfunctions, ranging from misfires to the inability to start the vehicle. Contact us today to learn more and discover how our sensors can protect your engine from performance issues.

SEIM - Your Partner for Reliable and High-Performance Solutions