SEIM Knock Sensor: Functioning, Role, Selection, and Installation

The knock sensor is a key component in modern engine management systems. It detects knocks, also known as "detonations," which can damage the engine.

What is a Knock Sensor?

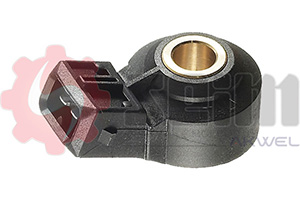

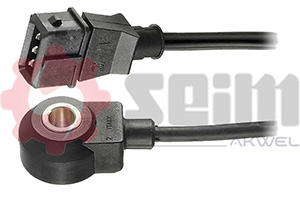

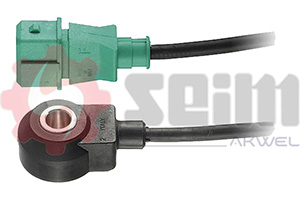

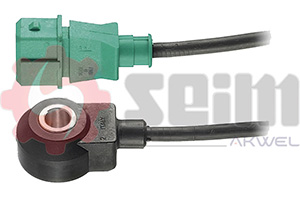

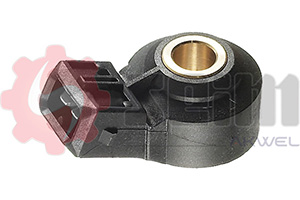

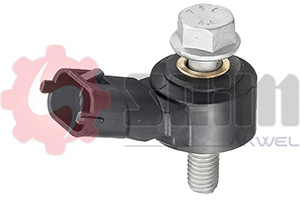

A knock sensor, or knock detection sensor, is a vibration-sensitive device mounted on the engine block. Its role is to detect specific sound waves of knocks, which are abnormal detonations caused by uncontrolled combustion of the air-fuel mixture in the cylinders.

Main Functions of the Knock Sensor:

- Detection of Abnormal Detonations: The sensor records abnormal vibrations generated by knocks that can damage the engine.

- Transmission of Information to the ECU (Engine Control Unit): When a knock is detected, the sensor sends a signal to the ECU, which adjusts the ignition timing to prevent damage.

- Engine Protection: By regulating the ignition timing, the knock sensor helps prevent serious engine damage, such as perforated pistons or damaged valves.

The knock sensor operates like a very sensitive microphone, capable of picking up high-frequency sounds associated with knock vibrations. When the ECU receives the signal, it retards the ignition to reduce pressure in the cylinders and stop detonations.

How to Choose a Knock Sensor?

To choose the right knock sensor, several factors must be considered:

- Compatibility with the Vehicle: Each engine has specific characteristics, and not all knock sensors are universal. Select a sensor that is compatible with your vehicle and engine model. Check original references or consult the manufacturer's specifications to avoid compatibility issues.

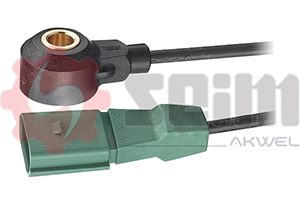

- Type of Sensor: There are two main types of knock sensors:

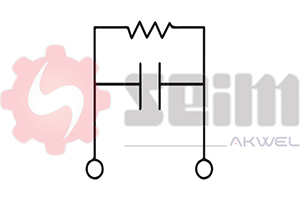

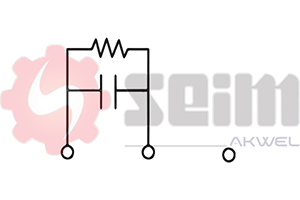

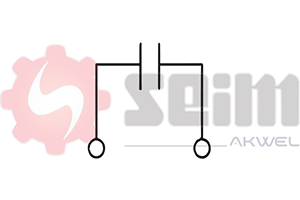

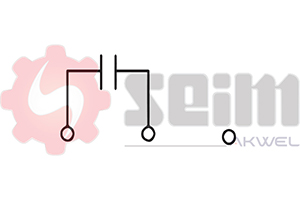

- Piezoelectric Sensor: This sensor converts vibrations into an electrical signal and is particularly sensitive to detonation vibrations.

- Resonance Sensor: This sensor is more selective and responds to specific frequencies associated with knocks.

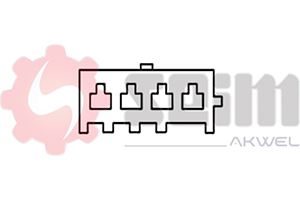

- Connectors: Ensure that the connector matches that of your vehicle.

Installing Knock Sensors

Installing knock sensors can be done by a professional or by yourself if you have the necessary skills. Here is a simplified guide to help you:

- Preparation: Before starting, disconnect the battery to avoid any risk of short circuit or damage to the ECU.

- Removal of the Old Sensor: The knock sensor is usually mounted directly on the engine block or cylinder head, near the cylinders for better vibration detection. Consult your vehicle’s manual for the exact location.

- Installation of the New Sensor: Position the new sensor in place, secure it, and reconnect the connectors.

- Function Test: After installation, reconnect the battery and start the engine to test functionality. If the ECU detects abnormal detonations, check the positioning or calibration of the sensor using a diagnostic tool.

Maintenance of Knock Sensors

To ensure the longevity and accuracy of your knock sensors, regular maintenance is necessary. Here are some tips:

- Cleaning: Keep the sensors clean to prevent dirt accumulation that could affect performance.

- Regular Inspection: Check the condition of the sensors regularly for any signs of wear or malfunction.

- Preventive Replacement: Replace the sensors at regular intervals according to the manufacturer’s recommendations to avoid unexpected failures.

Discover SEIM Knock Sensors Today!

The knock sensor is a fundamental element to protect your engine from damaging detonations. A faulty sensor can lead to premature engine wear and costly repairs. Contact us today to learn more and discover how our knock sensors can ensure your vehicle operates safely without the risk of detonation.

SEIM - Your Partner for Reliable and High-Performance Solutions